Depending on how groundwater is managed, tunnels are largely classified

into drainage type and non-drainage type.

The choice between these methods depends on the tunnel’s purpose, stability,

economic efficiency, and constructability (Korean Geotechnical Society).

| Type | Characteristics | Sub-types | Description | Hydrostatic Pressure |

|---|---|---|---|---|

| Drainage Type Tunnels | Method of draining groundwater that enters the tunnel | Full Drainage | Water flows into the entire tunnel cross-section and is discharged completely (e.g., water tunnels, tunnels under construction) |

Almost no hydrostatic pressure on concrete lining |

| Partial Drainage | Waterproofing membranes are installed only at the crown and sidewalls, guiding water to a single drainage point |

Minimal hydrostatic pressure | ||

| Non-Drainage Type Tunnels | Method of blocking groundwater inflow completely | - | Entire tunnel exterior is waterproofed to prevent water penetration | Hydrostatic pressure acts on concrete lining |

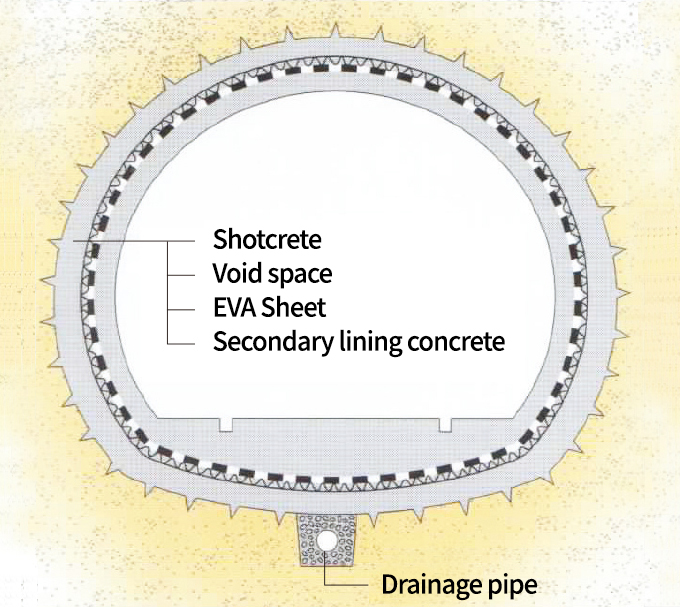

This method installs a waterproofing layer around the entire tunnel cross-section

and uses primary concrete or shotcrete to completely block groundwater infiltration.

In this case, the tunnel cross-section is designed to be nearly circular so that the internal

concrete can withstand water pressure, ensuring that the tunnel structure is supported by tensile stress.

The advantages of this method are that the tunnel interior remains clean and

no additional energy or equipment costs are required for drainage.

In addition, since there is no ground settlement caused by groundwater drainage,

damage to existing surface structures is minimized.

However, achieving 100% complete waterproofing is extremely difficult in practice, and this requires

significant costs for waterproofing and reinforcement works, as well as meticulous quality control during construction.

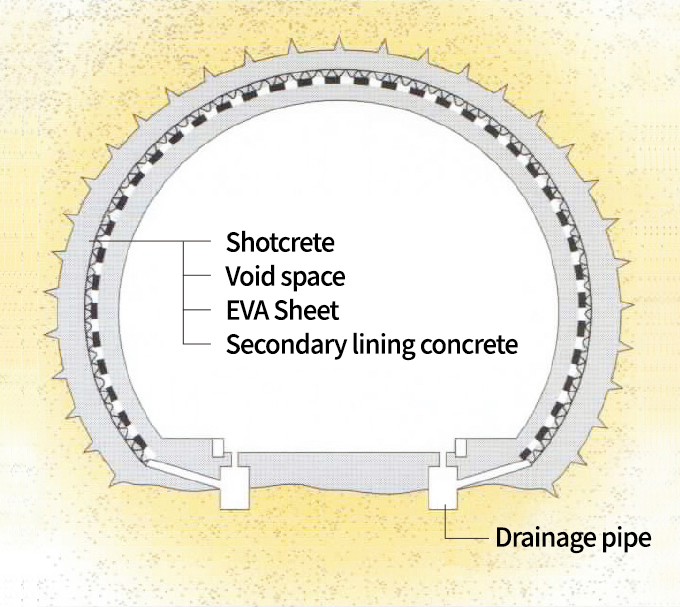

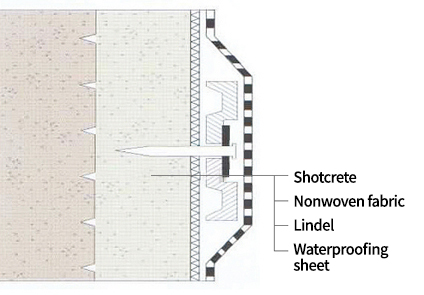

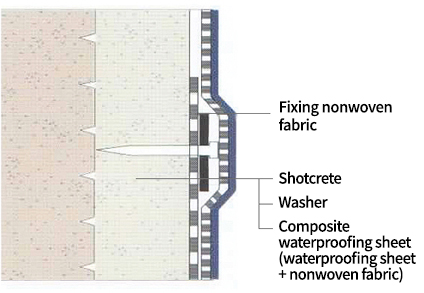

The waterproofing layer is installed only on the tunnel crown and sidewalls,

and groundwater infiltration is guided to the lower sidewalls through the permeability of the waterproofing material

or through an additional drainage layer, then discharged into internal drains.

This method is designed so that hydrostatic pressure does not act directly on the tunnel’s secondary lining concrete.

In high groundwater-level tunnel conditions (e.g., immersed tunnels), this method is structurally unavoidable.

During subway construction, depending on site conditions such as geological

structure, groundwater level, line intersections, and surface conditions,

either complete waterproofing or partial drainage waterproofing is selectively applied.

In principle, the partial drainage method is primarily adopted,

and the following principles are observed to ensure complete resolution of issues:

1. Completely relieve hydrostatic pressure acting on the secondary lining concrete.

2. Minimize groundwater inflow into the tunnel interior.

3. Guide surrounding groundwater to a central sump for proper treatment.

* Source: Study on the Utilization of Discharged Groundwater from Large Facilities /

Ministry of Construction & Transportation; Korea Construction & Transportation Technology Evaluation Institute

| Type | Advantages | Disadvantages |

|---|---|---|

| Complete Waterproofing |

|

|

| Partial Drainage |

|

|

| Separated Construction Method (ECB Sheet, EVA Sheet) | Integrated Construction Method (EVA Sheet) | |

|---|---|---|

|

|

|

| Site Preparation |

|

|

| Installation of Non-woven Fabric |

|

|

| Installation of Waterproof Sheet |

|

|

| Inspection |

|

|

| Category | Summary |

|---|---|

| Causes of Leakage | Concrete absorption, cracks, construction joints, etc. |

| Features of Sheet Waterproofing | Surface adhesion, excellent strength and temperature resistance, withstands microcracks, easy construction |

| Handling Inflow in Underpasses | Essential to block rainwater and groundwater inflow; sump capacity must reflect heavy rainfall and inflow volume |

| Drainage Method | Intermittent drainage (collect for a period, then quickly discharge) |

| Construction Characteristics | Difficult to repair, so perfect construction is required at the initial design stage |

| Methods for Ensuring Watertightness | Use admixtures, eliminate voids through vibration compaction |

| Crack Compensation | Cracks are inevitable → Self-sealing capability is important |

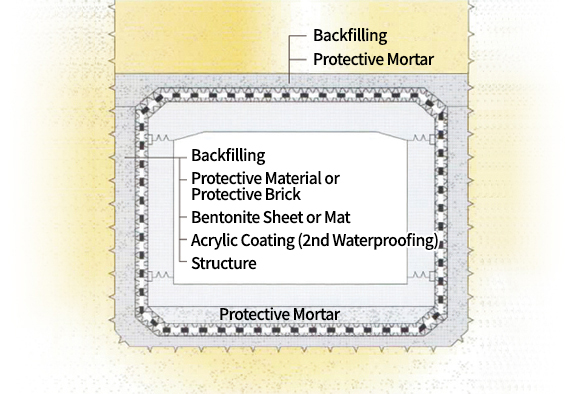

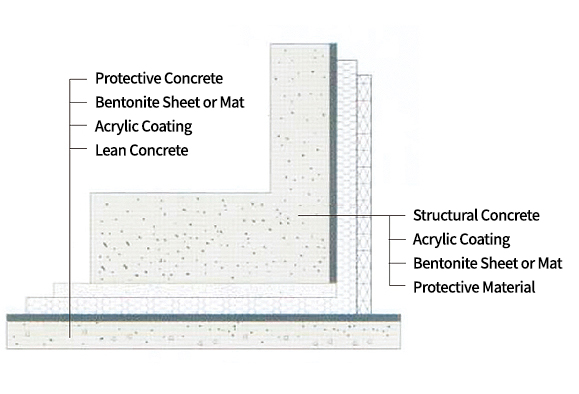

| Recommended Waterproofing Materials | Bentonite-based materials; performance maximized when combined with acrylic coating |

No special equipment or tools are required; construction is

simple and significantly shortens construction time.

Excellent self-sealing (crack compensation) performance.

Outstanding durability and permanence.

Easy treatment around rock anchors and penetrations.

Can be installed immediately

after formwork removal (even in moist conditions).

Being water-based, waterproofing work is possible even

in the presence of moisture, reducing construction time.

Easy to apply as a water-based material,

with excellent adhesion to concrete surfaces.

Allows sheet installation

using adhesion without damaging the structure.

Excellent compatibility with other

waterproofing methods, enhancing and maximizing performance.

Being water-based,

there is no risk of explosion due to solvent flammability.