Float

Float

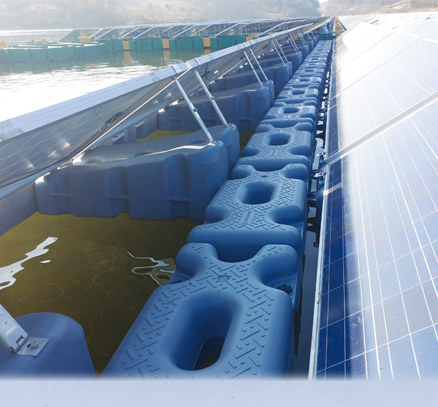

Minimizes deforestation. By utilizing unused water surface

and waterfront space, land use becomes more efficient.

Unlike mountainous areas with trees or structures, there are fewer obstacles

and no shadows are cast, resulting in higher power generation efficiency

and reduced reservoir evaporation.

Floating solar power plants can be installed in reservoirs or

lakes owned by cities, provinces, or the state, enabling

faster project implementation through direct contracts with the government.

Using integrated module floats allows installation without

additional structural processes, significantly lowering costs through

reduced material expenses, construction time, and installation costs.

In addition, applying bifacial modules enables a 15–25% increase in

output compared to conventional systems.

The new method using integrated module floats and surplus reflected light

energy is expected to become mainstream in domestic and global solar power

projects.

With reduced investment costs and maximized profitability,

it is expected to promote renewable energy development and

revitalize the solar energy market.

Shortened construction periods reduce installation costs,

and the use of bifacial modules

(and optional reflectors when needed)

allows maximum profitability.

| NO | Product Name | Type | Specifications/Dimensions | Product Image | Applications | |

|---|---|---|---|---|---|---|

| Form | Material | |||||

| 1 | Green Buoy 70 Green Buoy 90 Green Buoy 120 |

Injection Type | HDPE | 70L (839×373mm) 90L (905×400mm) 120L (992×425mm) |

|

Oysters, Scallops, etc. |

| 2 | Green Buoy 13 | Injection Type | HDPE | 13L (301×250mm) |  |

Seaweed, Gillnets, Fish Traps, etc. |

| 3 | Green Buoy 240 Green Buoy 280 |

Injection Type | HDPE | Ø240 (240×240mm) Ø280 (280×280mm) |

|

Seaweed, Kelp, etc. |

| 4 | Green Buoy 65 | Injection Type | HDPE | 65L (532×395mm) |  |

Oysters, Scallops |

| 5 | Green Buoy 67 with Ring |

Injection Type | HDPE | 68L (535×402mm) |  |

Oysters, Scallops, Seaweed, etc. |

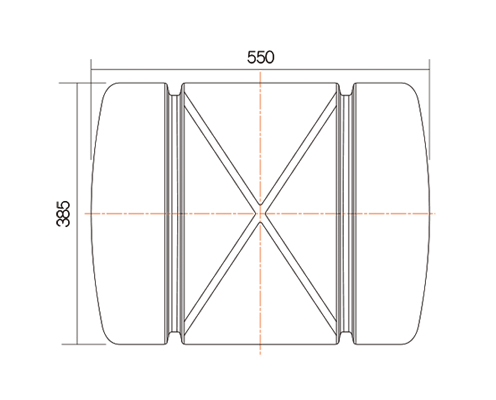

| 6 | Green Buoy 60-A | Injection Type | HDPE | 68L (550×400mm) |  |

Oysters, Scallops, Seaweed, etc. |

| 7 | Green Buoy 40 | Injection Type | HDPE | 40L (486×341mm) |  |

Oysters, Scallops, Seaweed, etc. |

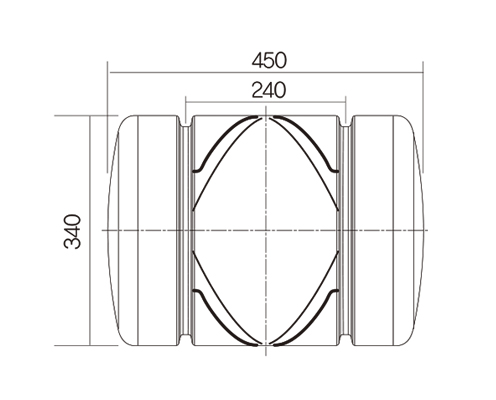

| 8 | Green Buoy 220 Green Buoy 320 |

Injection Type | HDPE | Ø220 (600×820mm) Ø320 (700×860mm) |

|

Large Aquaculture Buoys, etc. |

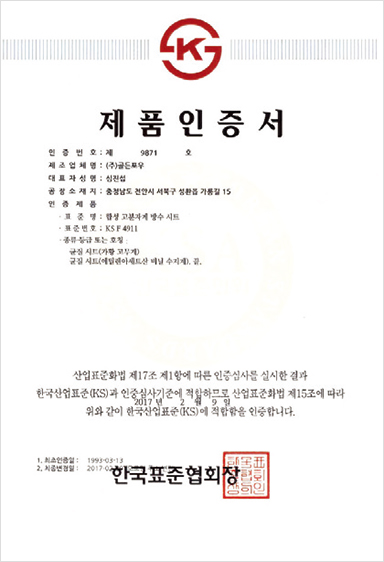

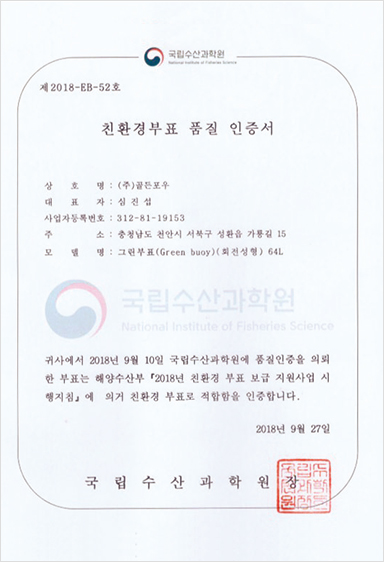

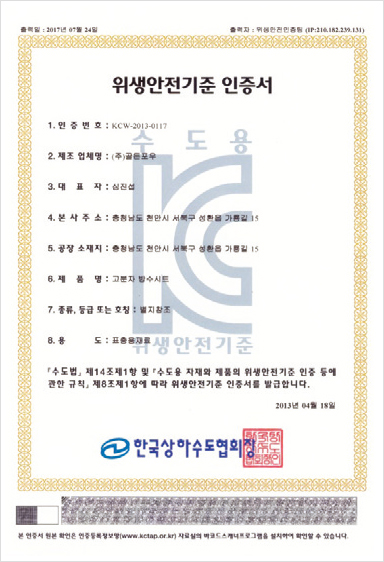

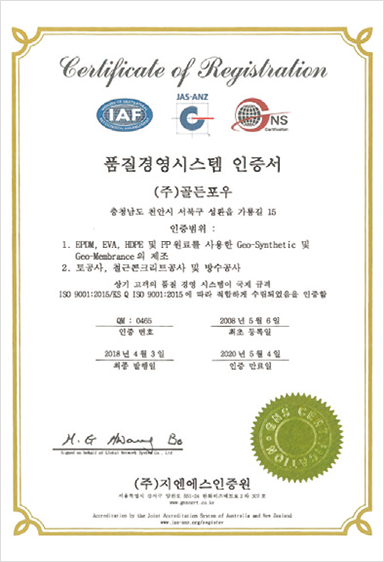

Eco-Friendly Green Buoy

Technology Transfer Agreement

Patent Certificate

Design Registration Certificate

Air Pack

Green Technology Certification

After injecting air into the “A” section, the valve in

the “B” section automatically closes due to internal

air pressure, preventing air from escaping.

Made of High Molecular HDPE with excellent environmental resistance,

stress crack resistance, and impact strength.

100% recyclable (High Density Polyethylene)

Uses filling materials with minimal waste relative to expansion pressure,

certified as a carbon-reducing green technology,

making it lightweight and easy to handle.

Filling is done in independent cell layers, maintaining individual buoyancy.

Designed with rope attachment grooves for convenient handling during work.

Uses highly visible color schemes for excellent visibility even in low light.

Stable under UV exposure.

Low biofouling adhesion, easy to remove attached organisms.

| Test Item | Performance Standard | Remarks | |||||

|---|---|---|---|---|---|---|---|

| Buoyancy (kgf) | [(Rated Volume (L) * 0.7) - Self Weight (kgf)] or more | 55.4 | |||||

| Hydrostatic Pressure Resistance | No cracks, breaks, or tears on the buoy | None | |||||

| Accelerated Weathering (2,000 hours) | No surface cracks or damage | None | |||||

| Buoyancy after Injection Joint Fatigue Test |

90% or more | 100% | |||||

| Environmental Hazard |

Organotin Compounds | Should not be detected | Not detected | ||||

| Heavy Metals (mg/kg) (Sb, Cr, As, Pb, Ba, Hg, Cd, Se) |

Antimony | 60 or less | Chromium | 60 or less | Within standard | ||

| Arsenic | 25 or less | Lead | 90 or less | ||||

| Barium | 1,000 or less | Mercury | 60 or less | ||||

| Cadmium | 75 or less | Selenium | 500 or less | ||||

| Flame Retardants (mg/kg) |

PBBs, PBDEs, TBBBPA, HBCD should not be detected | Not detected | |||||

φ385mm × 550mm 60L

φ340mm × 450mm 38L

70L, 90L, 120L

Contains airbags to provide buoyancy against external scratches

Round design applied to maximize hydrostatic stability

Minimizes wave-induced vibration.

Prevents detachment of shellfish like oysters and mussels

Excess air is forcibly injected to increase

air density, allowing it to withstand certain water pressure

Reinforced air density to prevent deformation even if partially submerged

Contains airbag to support self-weight, preventing sinking if damaged

Ensures structural stability through air injection